Secure Supplies Group

Fueling Healthy Communities

Power Gas Architecture | Developer

Secure Supplies Group

Power Supplies Electrolyzers AC DC

Solar to Hydrogen

-

AC to DC

-

DC to DC

-

Voltrolysis

-

Electrolysis

-

Electroplating

-

Caustic Soda

-

DC Arc Furnace Heating

-

CED Coating

-

Coppr Electowinning

-

SeaWater Treatment

-

Water to Hydrogen

-

DC power supplies used for Data Center, Crypto Mining Farm

Data Center Rack Powe Parameters:

3 phase 220V, 380V,480V(+-10%) AC input,50Hz/60Hz product description Output regulation range: 0-100%

Control mode: constant voltage selectable Air cooling/water cooling Accuracy:<1%

Power factor: ≥0.93 IP degree: IP30 Insulation grade: B Working mode: 100% 24 hours continuous...

Products

Electroplating Transformer Rectifier With IGBT

This rectifier adopts high frequency IGBT as semiconductor component and PWM modulation technology. It is modular structure design, easy to expand output current capacity, several rectifier modules could be connected in parallel and mounted in stack up to 20 modules to make more current single rectifier. has independent power modules, each module could output independently or output in parallel connection.

Input line voltage(V) 380AC +-10%

Input frequency 50HZ/60HZ

IGBT Power Supply for Electrolyzer Hydrogn Generation CE Compliant

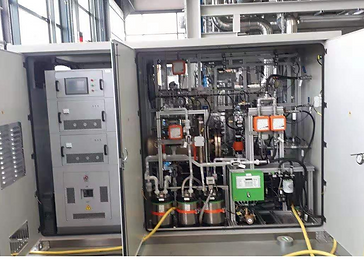

IGBT Power Supply for Electrolyzer Hydrogen Generation CE Compliant 1. IGBT Power Supply for Electrolyzer for hydrogen Generation Video 2. Reference Picture of IGBT Power Supply for Electrolyzer for hydrogen Generation 3. Principle of Electrolyzer for hydrogen Generation Providing DC power..

Working duty

100% 24 hours continuous running

Input voltage

220V/380/415V/480V AC ±10% 3 phase 4 line, 50-60Hz

13kA 12V Power Supply For NF₃ Electroysis

This rectifier is suitable for electrochemistry process, such as electroplating, electrolysis, anodizing, electrowinning, electrorefining etc.

To provide stable DC power supply.

Working principle:

Three phase AC input is converted to DC through rectification and filter, then DC voltage is transformed to DC output through phase shift full bridge PWM DC/DC converter.

Main technical data:

1. AC Input

1.1 Input AC power

Rectifier @ AC380V+/-10%, 3 phase 3 wire 60Hz

UPS @ AC 110V, 1phase, 60Hz

2. DC Output

2.1Rated Output13000A 12V

2.2Output mode and range Constant Current10%-100% of rated value Constant Voltage, 10%-100% of rated value

2.3 Duty 100% full load

2.4Accuracy<1%

3. Electrical Features

3.1 Application Electrolysis NF₃

3.2 Regulation modeIGBT PWM

3.3 ControlLocal touch panel control, no remote control

3.4Efficiency90% @ 12V 13000A 88% @ 10.8V 13000A 87% @ 9.6V 13000A

3.5Power Factor (Full load) ≥0.90 @ 9.6V-12V 13000A

3.6Cooling Method(specify altitude if air cooling) Forced air cooling

3.7IP degree IP30

3.8Insulation Grade F

3.9Temperature riseB

3.10 Working ModeContinuous

3.11Alarm typeAudible and visual alarm (on rectifier front panel and touch panel)

4.Withstanding

4.1Primary to secondary2000V rms 1min

4.2Primary to PE 2000V rms 1min

4.3Control circuit to PE 1500V rms 1min

4.4 Secondary to PE 1500V rms 1min

5. Mechanic Features

5.1 Coating and PaintingRAL 7035

2500A18V Constant Current/Voltage DC Power Supply For Electrolysis

Application This is 2500A18V Constant Current/Voltage DC Power Supply for Electrolysis , water cooling, 3 modules in parallel, 2500A18V*2+1000A10V*1 module structure. Specification Working condition Cooling water requirement: l Used indoors, ambient temperature: 0℃ ~ + 5 0℃. l Relative humidity:...

This is 2500A18V Constant Current/Voltage DC Power Supply for Electrolysis, water cooling, 3 modules in parallel, 2500A18V*2+1000A10V*1 module structure.